Isima yo hasi

Amakuru y'ibicuruzwa

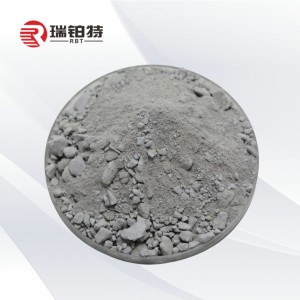

| izina RY'IGICURUZWA | Kwangirika |

| Ibyiciro | Isima yo hasi isukuye / Imbaraga nyinshi zishobora guterwa / alumina yo hejuru / Yoroheje |

| Ibigize | Igiteranyo cyo guhunika, ifu na binders |

| Ibiranga | 1. Kubaka byoroshye 2. Kurwanya icyapa cyiza 3. Kurwanya ruswa neza 4. Kurwanya umuriro mwiza 5. Kuzigama ingufu no kurengera ibidukikije |

| Ibicuruzwa | Isima yo hasi | Imbaraga Zirenze |

| Ibisobanuro | Amashanyarazi make ya sima yerekeza kubintu bishya hamwe na sima nkeya cyane.Ubusanzwe sima yibikoresho byangiritse ni 15% kugeza kuri 20%, naho sima yibikoresho bya sima nkeya ni 5%, ndetse bimwe bigabanuka kugeza kuri 1% kugeza 2%. | Imbaraga nyinshi zidashobora kwihanganira imyanda igizwe nimbaraga nyinshi zegeranya, imyunyu ngugu, imbaraga nyinshi hamwe hamwe na anti crack na agent idashobora kwambara. |

| Ibiranga | Kurwanya ubushyuhe bwumuriro, kurwanya slag, no kurwanya isuri byateye imbere cyane, birenze amatafari asa. | Imbaraga nyinshi, kurwanya cyane kwambara, kurwanya ingaruka, kurwanya isuri, kurwanya amavuta, kugenzura imiterere uko bishakiye, ubunyangamugayo bukomeye, ubwubatsi bworoshye, imikorere myiza yubwubatsi, na serivisi ndende. |

| Porogaramu | 1. Gutondekanya itanura ritandukanye ryokoresha ubushyuhe, itanura rishyushya, itanura rya shitingi, itanura ryizunguruka, ibifuniko by itanura ryamashanyarazi, itanura ritanura; 2. Kwiyungurura-sima-sima ikwiranye nubushyuhe bwo hejuru bwo gutera imbunda ya spray metallurgie hamwe na peteroli ya catalitiki ya catalitike yamenagura imyambarire idashobora kwangirika, umurongo winyuma wo gushyushya itanura ryamazi akonje, nibindi. | Imirongo irwanya kwambara ya slag sluice,ubutare, amabuye yamakara, hopper na silo muri metallurgie, amakara, ingufu zumuriro, imiti,sima nizindi nganda, hamwe nitanura riturika rivanga silo, gucumura silo, ibiryo, pelletizer, nibindi. |

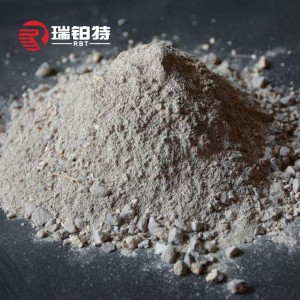

| Ibicuruzwa | Hejuru ya Alumina | Umucyo woroshye |

| Ibisobanuro | Amashanyarazi menshi-alumina yangacastable ikozwe mubikoresho-byinshi bya aluminanka agregate na poro, kandi byongewehohamwe na binders. | Umucyo woroheje ufite ubunini buke bukozwe muri sima ya aluminium, ibikoresho byiza bya alumina nziza, ceramsite, ninyongera. |

| Ibiranga | Ifite imbaraga zo gukanika hamwe nubushyuhe bwiza bwumuriro, kurwanya abrasion nibindi bintu. | Ubucucike buke, ubworoherane buke bwumuriro, ingaruka nziza zo gukingira ubushyuhe, imbaraga zo gukomeretsa cyane, aside aside na aside irwanya ruswa, kubika ubushyuhe, kubika ubushyuhe, no gufata amazi make. |

| Porogaramu | Ikoreshwa cyane cyane nk'imbere y'imbere ya boiler, itanura ritanura rishyushye, amashyiga ashyushya, itanura ceramic nandi matanura. | Umuyoboro woroheje urashobora gukoreshwa murwego rwo gutwika ubushyuhe bwamashyiga yubushyuhe bwo hejuru hamwe nibikoresho bikoreshwa mugutondekanya imiyoboro itandukanye ya gazi yubushyuhe bwo hejuru. |

Ironderero ry'ibicuruzwa

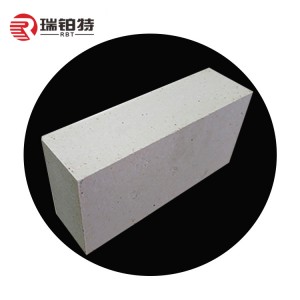

| izina RY'IGICURUZWA | Isima yo hasi | |||||

| INDEX | RBTZJ-42 | RBTZJ-60 | RBTZJ-65 | RBTZJS-65 | RBTZJ-70 | |

| Ubushyuhe bwo Gukora | 1300 | 1350 | 1400 | 1400 | 1450 | |

| Ubucucike bwinshi (g / cm3) 110 ℃ × 24h≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Imbaraga Zunamye 110 ℃ × 24h (MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Imbaraga zo gukonjesha (MPa) ≥ | 110 ℃ × 24h | 25 | 30 | 35 | 35 | 40 |

| CT ℃ × 3h | 50 1300 ℃ × 3h | 55 1350 ℃ × 3h | 60 1400 ℃ × 3h | 40 1400 ℃ × 3h | 70 1400 ℃ × 3h | |

| Guhindura umurongo uhoraho @ CT ℃ × 3h (%) | -0.5 ~ + 0.5 1300 ℃ | -0.5 ~ + 0.5 1350 ℃ | 0 ~ + 0.8 1400 ℃ | 0 ~ + 0.8 1400 ℃ | 0 ~ + 1.0 1400 ℃ | |

| Kurwanya Ubushyuhe (1000 ℃ amazi) ≥ | - | - | - | 20 | - | |

| Al2O3 (%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| CaO (%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| Fe2O3 (%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

Gusaba

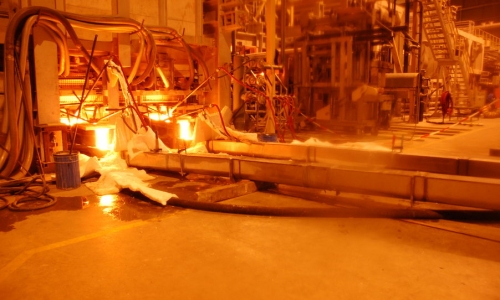

Inganda zicyuma nicyuma:Ahanini ikoreshwa mukubungabunga no gutekesha itanura ryamashanyarazi arc, itanura ryo gukora ibyuma, ingoro nibindi bikoresho.

Inganda zidafite ferrous:Ikoreshwa mu gusya no gusana umuringa, aluminium, zinc, nikel hamwe nandi matanura ya fer fer fer na feri.

Inganda zikirahure:Ikoreshwa mukubungabunga no gutobora imirimo yitanura ryibirahure, itanura rya annealing nibindi bikoresho.

Inganda zubaka inganda: zikoreshwa mukubungabunga no gutobora ibikoresho byubaka ibikoresho nka sima rotary itanura na gypsum.

Inganda zikora imiti:Ikoreshwa mukubungabunga no gutobora ibikoresho bya chimique yubushyuhe bwo hejuru nka catalitike yamenagura itanura na gaze.

Inganda zubutaka:Ikoreshwa mukubungabunga no gusana ibikoresho byububiko bwibumba nkibikoresho bya tunnel hamwe nitanura rya shitingi.

Ububiko & ububiko

Ibibazo Bikunze Kubazwa

Ukeneye ubufasha?Wemeze gusura amahuriro adutera inkunga kugirango ubone ibisubizo kubibazo byawe!

Turi uruganda nyarwo, uruganda rwacu ruzobereye mugukora ibikoresho bivunika mumyaka irenga 30.Turasezeranye gutanga igiciro cyiza, serivise nziza yo kugurisha na nyuma yo kugurisha.

Kuri buri gikorwa cyo kubyaza umusaruro, RBT ifite sisitemu yuzuye ya QC yo guhimba imiti nibintu bifatika.Tuzagerageza ibicuruzwa, kandi icyemezo cyiza kizoherezwa hamwe nibicuruzwa.Niba ufite ibisabwa byihariye, tuzagerageza uko dushoboye kugirango tubyemere.

Ukurikije ubwinshi, igihe cyo gutanga kiratandukanye.Ariko turasezeranya kohereza vuba bishoboka kandi bifite ireme.

Birumvikana, dutanga ingero z'ubuntu.

Nibyo, byanze bikunze, urahawe ikaze gusura sosiyete ya RBT nibicuruzwa byacu.

Nta karimbi, turashobora gutanga igitekerezo cyiza nigisubizo ukurikije ibihe byawe.

Tumaze imyaka irenga 30 dukora ibikoresho byo kwanga, dufite inkunga ikomeye ya tekiniki hamwe nuburambe bukomeye, dushobora gufasha abakiriya gukora itanura ritandukanye no gutanga serivisi imwe.