Icyatsi cya Silicon Carbide

Amakuru y'ibicuruzwa

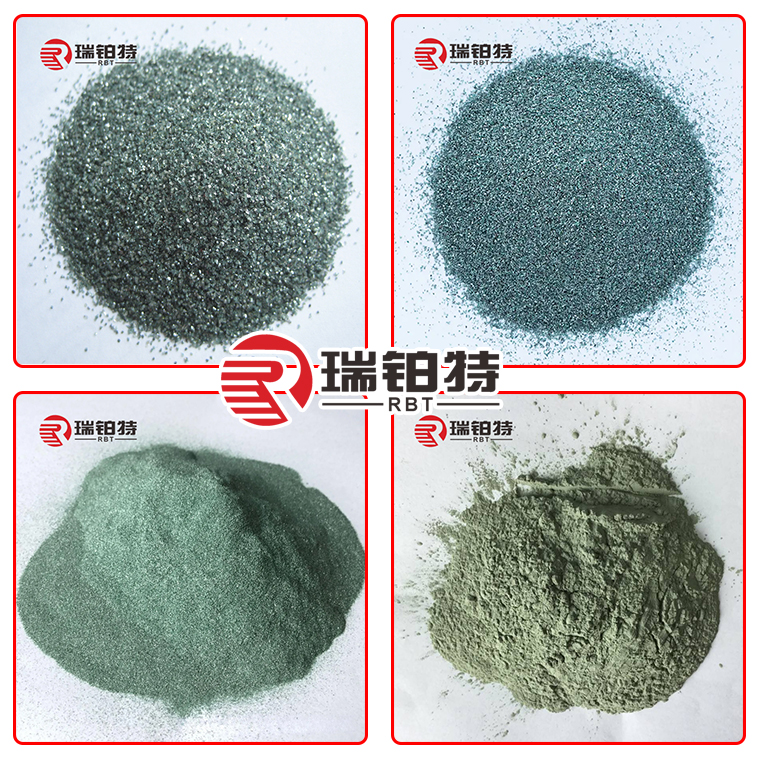

Icyatsi cya silicon karbide umucangani umuntu wakozwe n'abantu bafite imiti ya SiC. Igizwe ahanini numusenyi wa quartz, peteroli ya kokiya (cyangwa kokiya yamakara) hamwe nigitaka binyuze mumashanyarazi yubushyuhe bwo hejuru mu itanura rirwanya. Icyatsi cya silicon karbide umucanga nicyatsi kibisikandi ifite byinshi biranga nibikorwa.

Gutunganya imikorere

Gusya cyane:Imiterere yibice hamwe nubukomezi bituma igira uburyo bwiza bwo gusya, bushobora gukuraho vuba umwanda na oxyde hejuru yumurimo wakazi.

Umutungo mwiza wo kwikarisha:Ingano nubunini bingana kandi bifite inkingi yicyuma, itanga imitungo iringaniye yo kwikarisha nkibikoresho byo gukata kandi ikanagabanya kugabanya ibikoresho byaciwe.

Guhuza n'imihindagurikire y'ikirere:Irashobora guhuzwa neza nogutandukanya ibintu bitandukanye kugirango itunganyirizwe neza kandi neza.

Ibintu bifatika

| Ibara | Icyatsi |

| Ifishi ya Crystal | Polygon |

| Mohs Gukomera | 9.2-9.6 |

| Micro Gukomera | 2840 ~ 3320kg / mm² |

| Ingingo yo gushonga | 1723 |

| Ubushyuhe ntarengwa bwo gukora | 1600 |

| Ubucucike nyabwo | 3.21g / cm³ |

| Ubucucike bwinshi | 2.30g / cm³ |

Ibisobanuro birambuye

Imbonerahamwe yo Kugereranya Ingano

| Grit No. | Ubushinwa GB2477-83 | Ubuyapani JISR 6001-87 | Amerika ANSI (76) | 欧洲磨料 FEPA (84) | 国际 ISO (86) |

| 4 | 5600-4750 |

| 5600-4750 | 5600-4750 | 5600-4750 |

| 5 | 4750-4000 |

| 4750-4000 | 4750-4000 | 4750-4000 |

| 6 | 4000-3350 |

| 4000-3350 | 4000-3350 | 4000-3350 |

| 7 | 3350-2800 |

| 3350-2800 | 3350-2800 | 3350-2800 |

| 8 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 |

| 10 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 |

| 12 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 |

| 14 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 |

| 16 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 |

| 20 | 1180-1000 | 1180-1100 | 1180-1000 | 1180-1000 | 1180-1000 |

| 22 | 1000-850 | - | - | 1000-850 | 1000-850 |

| 24 | 850-710 | 850-710 | 850-710 | 850-710 | 850-710 |

| 30 | 710-600 | 710-600 | 710-600 | 710-600 | 710-600 |

| 36 | 600-500 | 600-500 | 600-500 | 600-500 | 600-500 |

| 40 | 500-425 | - | - | 500-425 | 500-425 |

| 46 | 425-355 | 425-355 | 425-355 | 425-355 | 425-355 |

| 54 | 355-300 | 355-300 | 355-297 | 355-300 | 355-300 |

| 60 | 300-250 | 300-250 | 297-250 | 300-250 | 300-250 |

| 70 | 250-212 | 250-212 | 250-212 | 250-212 | 250-212 |

| 80 | 212-180 | 212-180 | 212-180 | 212-180 | 212-180 |

| 90 | 180-150 | 180-150 | 180-150 | 180-150 | 180-150 |

| 100 | 150-125 | 150-125 | 150-125 | 150-125 | 150-125 |

| 120 | 125-106 | 125-106 | 125-106 | 125-106 | 125-106 |

| 150 | 106-75 | 106-75 | 106-75 | 106-75 | 106-75 |

| 180 | 90-63 | 90-63 | 90-63 | 90-63 | 90-63 |

| 220 | 75-53 | 75-53 | 75-53 | 75-53 | 75-53 |

| 240 | 75-53 | - | 75-53 | - |

Ironderero ry'ibicuruzwa

| Ingano ya Grit | Ibigize imiti% (Kuburemere) | ||

| SiC | F · C. | Fe2O3 | |

| 12 # -90 # | ≥98.50 | ≤0.20 | 60.60 |

| 100 # -180 # | ≥98.00 | ≤0.30 | ≤0.80 |

| 220 # -240 # | ≥97.00 | ≤0.30 | ≤1.20 |

| W63-W20 | ≥96.00 | ≤0.40 | ≤1.50 |

| W14-W5 | ≥93.00 | ≤0.40 | ≤1.70 |

Gusaba

1. Abrasive:Carbide yicyatsi kibisi ikoreshwa cyane nkibikoresho byangiza inganda zitandukanye, harimo amamodoka, icyogajuru, gukora ibyuma, n imitako. Ikoreshwa mu gusya, gukata, no gusya ibyuma bikomeye nubutaka.

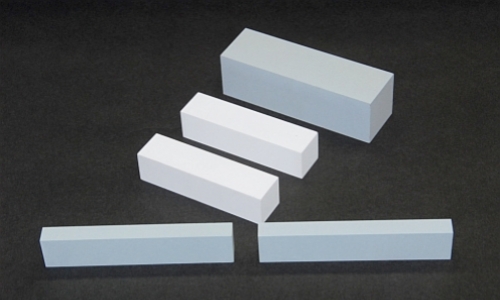

2. Kwanga:Carbide yicyatsi kibisi nayo ikoreshwa nkibikoresho bivunika mubushyuhe bwo hejuru nkitanura n’itanura bitewe nubushyuhe bwinshi bwumuriro no kwaguka kwinshi.

3. Ibyuma bya elegitoroniki:Carbide yicyatsi kibisi ikoreshwa nkibikoresho byububiko bwa elegitoronike nka LED, ibikoresho byamashanyarazi, nibikoresho bya microwave kubera amashanyarazi meza cyane hamwe nubushyuhe bwumuriro.

4. Imirasire y'izuba:Carbide yicyatsi kibisi ikoreshwa nkibikoresho byo gukora imirasire yizuba bitewe nubushyuhe bwinshi bwumuriro no kwaguka kwinshi kwubushyuhe, bifasha mukwirakwiza ubushyuhe butangwa mugihe cyo gukora imirasire yizuba.

5. Metallurgie:Carbide yicyatsi kibisi ikoreshwa nkibintu byangiza umubiri mu gukora ibyuma nicyuma. Ifasha mugukuraho umwanda mubyuma bishongeshejwe no kuzamura ubwiza bwibicuruzwa byanyuma.

6. Ubukorikori:Carbide yicyatsi kibisi ikoreshwa nkibikoresho fatizo byo gukora ubukerarugendo bugezweho nkibikoresho byo gutema, ibice birwanya kwambara, hamwe nubushyuhe bwo hejuru bitewe nuburemere bwayo bwinshi, imbaraga nyinshi, hamwe nubushyuhe buhebuje.

Ububiko & ububiko

| Amapaki | 25KG Umufuka | 1000KG Umufuka |

| Umubare | Toni 24-25 | Toni 24 |

Umwirondoro w'isosiyete

Shandong Robert Ibikoresho bishya Co, Ltd.iherereye mu mujyi wa Zibo, Intara ya Shandong, mu Bushinwa, ikaba ari uruganda rukora ibikoresho. Turi ikigo kigezweho gihuza ubushakashatsi niterambere, umusaruro, kugurisha, gushushanya itanura nubwubatsi, ikoranabuhanga, nibikoresho byohereza ibicuruzwa hanze. Dufite ibikoresho byuzuye, tekinoroji igezweho, imbaraga za tekiniki zikomeye, ubuziranenge bwibicuruzwa, nicyubahiro cyiza. Uruganda rwacu rufite ubuso bungana na hegitari 200 kandi umusaruro wumwaka wibikoresho byangiritse ni toni 30000 naho ibikoresho byo kuvunika bidafite ishusho ni toni 12000.

Ibicuruzwa byingenzi byibikoresho byangiritse birimo:ibikoresho byo kunanura alkaline; ibikoresho bya aluminium silicon; ibikoresho bitavunitse; ibikoresho byo gukuramo ubushyuhe; ibikoresho bidasanzwe byo kuvunika; ibikoresho byo kunanura imikorere ya sisitemu yo gukomeza.

Ibibazo Bikunze Kubazwa

Ukeneye ubufasha? Wemeze gusura amahuriro adutera inkunga kugirango ubone ibisubizo kubibazo byawe!

Turi uruganda nyarwo, uruganda rwacu ruzobereye mu gukora ibikoresho bivunika mumyaka irenga 30. Turasezeranye gutanga igiciro cyiza, serivise nziza yo kugurisha na nyuma yo kugurisha.

Kuri buri gikorwa cyo kubyaza umusaruro, RBT ifite sisitemu yuzuye ya QC yo guhimba imiti nibintu bifatika. Tuzagerageza ibicuruzwa, kandi icyemezo cyiza kizoherezwa hamwe nibicuruzwa. Niba ufite ibisabwa byihariye, tuzagerageza uko dushoboye kugirango tubyemere.

Ukurikije ubwinshi, igihe cyo gutanga kiratandukanye. Ariko turasezeranya kohereza vuba bishoboka kandi bifite ireme.

Birumvikana, dutanga ingero z'ubuntu.

Nibyo, byanze bikunze, urahawe ikaze gusura sosiyete ya RBT nibicuruzwa byacu.

Nta karimbi, turashobora gutanga igitekerezo cyiza nigisubizo ukurikije ibihe byawe.

Tumaze imyaka irenga 30 dukora ibikoresho byo kwanga, dufite inkunga ikomeye ya tekiniki hamwe nuburambe bukomeye, dushobora gufasha abakiriya gukora itanura ritandukanye no gutanga serivisi imwe.